- info@istpumpen.com

- 02261 701430

Innovation und Fortschritt so lautet der Leitsatz bei IST. Wo Flüssigkeiten und viskose Medien transportiert, dosiert und abgefüllt werden sollen, sorgen wir für Bewegung. Mit flexiblen, zuverlässigen und wirtschaftlichen Pumpensystemen, einer kompetenten Beratung und unserem umfangreichen Zubehörprogramm. Erfahrung ist die Grundlage, auf der auch anspruchsvollste technologische Herausforderungen zuverlässig gemeistert werden. Technologische Kompetenz und die richtigen Produkte gepaart mit Flexibilität und exzellenten Dienstleistungen ermöglichen unseren Kunden schnelle und wirtschaftliche Leistungen.

Für unsere Kunden halten wir für die meisten Pumpensysteme fast alle Verschleiß- und Ersatzteile auf Lager. Wir wissen wie wichtig es ist, einen Produktionsstillstand zu vermeiden. Deshalb haben wir auch für die Notfälle einen Expresslieferdienst. Kurze Reaktionszeiten, sofortige Lieferung und kompromissloser Service: das hält Ihre Produktion am laufen.

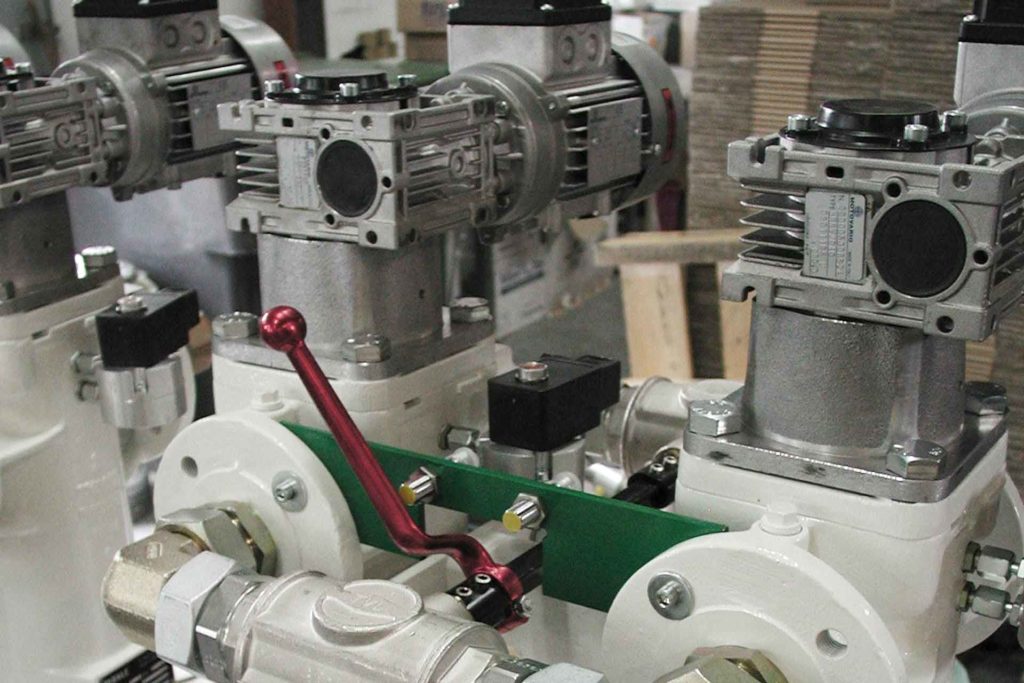

Unsere Entwicklung ist verantwortlich für die Konstruktion von Anlagen die optimal in die Produktionsabläufe unserer Kunden integriert werden. XX umgesetzte Projekte in verschiedenen Branchen zeichnen unsere Entwicklung aus. Die perfekte Zusammenarbeit mit den Kunden ist der Grundstein einer zukunftsträchtigen Investition.

Hohe Qualitätsansprüche und viel Erfahrung zeichnen unsere Konstruktionsabteilung aus.

Hausinterne Vormontage und darauffolgende Testläufe sind der Garant für reibungslose Installation. Der Kunde erhält perfekt konzipierte Ergänzung für seine Produktionsprozesse.

Mit unserem Know How in Verfahrens- und Automatisierungstechnik bieten wir den Kunden die Möglichkeit, eine fortschritliche Ergänzung der bestehenden Produktionsanlagen zu entwickeln. Wir realisieren die Projekte von der Idee bis zur Inbetriebnahme.

Jede Branche stellt unterschiedliche Anforderungen. Klimatische Bedingungen, Beförderung unterschiedlichster Viskositäten und der Einsatz hochwertiger Materialien haben uns über die Jahre sehr viel Erfahrung eingebracht. Davon profitieren unsere Kunden in höchstem Maße. Überzeugen Sie sich selbst und schauen sich unsere Referenzen an.

Die Vormontage und Testläufe werden hier im Haus gefahren, damit jede Fehlerquelle ausgeschlossen werden kann. Jeder Kunde kann finale Anpassungen vornehmen, so dass die Montage und Inbetriebnahme schnell, reibungslos und unkomplieziert erfolgt. Langfristige Kundenbeziehungen basieren auf der Zufriedenheit des Kunden und der Zuverklässigkeit des Lieferanten.

Gründung der IST Pumpen als Personengesellschaft.

Mit Erfahrungen aus dem Flugzeugbau und erfolgreichem Vertrieb, gründete 1998 der Dipl.Ing. Ingo Steiniger, die IST Pumpen und Dosiertechnik GmbH. Durch zahlreiche Auslandskontakte und einem organisierten Vertrieb, wuchs die IST Pumpen schnell und belieferte große Konzerne.

Bereits nach kurzer Zeit wurden Mitarbeiter eingestellt um der Nachfrage gerecht zu werden. Die Wertschätzung der Konzerne führten zu ein guter Auftragslage.

Schnell wuchs die eigene Produktpalette und es wurden Entwicklungen auf Kundenwunsch durch geführt.

Dazu wurde der Markenname „Blagdon“ der Harrison Group übernommen. Dadurchentstanden neue Entwicklungen. Besonders die BIBER Pumpen und die IST Faß- und Behälterentleerungssysteme führten früh zu weiteren großen Kunden, von der Pharma- und Lebensmittelindustrien und anderen Industrien, wie Automobil und Chemie.

Übernahme der IST Idel Maschinenbau GmbH und Integration in die IST Pumpen.

Aufgrund der großen Nachfrage wurde ein eigener Maschinenpark mit Drehen, Fräsen und Stahlbau notwendig.

Die Logik daraus war, daß der Anlagenbau wichtig wurde. Ein Auftrag aus Saudi Arabien von Hochdrucksystemen für die Öl- und Gasindustrie führte dazu, daß das Wachstum noch einmal größer wurde.

Eröffnung der Fertigung in Bergneustadt, jetzt vier Standorte.

Umzug in ein neues Firmengebäude. Zusammenlegung von 3 Standorten. Firmengebäude „Enselskamp 3 -5 in Wiehl Marienhagen wird bezogen.

© 2018 IST Pumpen

Realisierung & Umsetzung durch E&W Consulting GbR